Packaging is essential in sectors where bulk goods must be kept, moved, and handled effectively. Of the several options on hand, FIBC Super Sacks (Flexible Intermediate Bulk Containers) stand out as the gold standard in bulk packaging. Whether it’s agricultural, construction, chemicals, food processing, or mining, FIBC bags provide the ideal mix of strength, adaptability, and affordability.

This blog will cover FIBC Super Sacks, their advantages, kinds, applications, standards, and recommended measures for safe handling and storage.

An FIBC Super Sack is

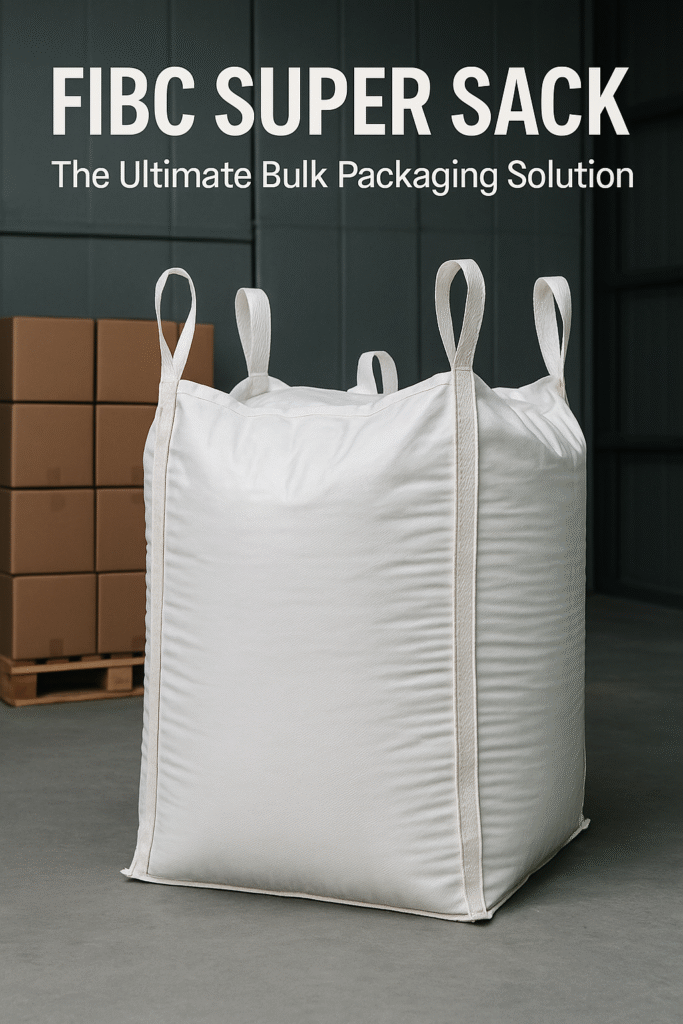

Made of woven polypropylene (PP), FIBC Super Sack is a big, robust bag meant for bulk storage and transportation of dry flowable goods. Often used interchangeably with FIBC, the phrase “super sack” refers to containers that usually hold between 500 kg and 2,000 kg (1,100 to 4,400 pounds).

Though they can carry a lot, FIBCs are thin and foldable, which makes them a good bulk packing option for many different sectors.

Main Characteristics of FIBC Super Sacks

- Depending on the design, can transport up to 2 tonnes of stuff.

- Available in various forms, sizes, loop patterns, and filling/discharge choices.

- Can be folded and stacked to save storage and transportation space.

- Replaces several tiny bags, hence lowering packaging and labour expenses.

- Available with liners and coatings for moisture-sensitive items.

- Reusable and recyclable materials help to make them sustainable.

FIBC Super Sack Varieties

Depending on handling and use requirements, FIBCs come in several designs:

A Type A FIBC

- Composed of conventional woven polypropylene.

- No static defence.

- Appropriate for non-flammable, non-combustible materials.

Type B FIBC

- Like Type A, but with low breakdown voltage.

- Offers little defence against propagating brush discharges.

- Still inappropriate in explosive settings.

Type C FIBC (Conductive Bags)

- Woven into the fabric, conductive strands make up

- Filling and discharge require grounding.

- Perfect for explosive settings and flammable materials.

Type D FIBC (Antistatic Bags)

- Stops static accumulation without grounding.

- Safe for usage near flammable gases or combustible dust.

Typical FIBC Configurations

FIBCs are quite flexible. Among the more frequent changes are:

- Structural kinds based on stitching and side panels for U-Panel and Circular Bags.

- Standard lifting design for cranes and forklifts, 4-Loop Bags.

- Duffel Top or Spout Top For simple filling.

- Depending on emptying requirements, discharge spout or flat bottom.

- Baffle Bags For improved stability and stacking, keep a square form.

Industries Using Super Sacks FIBC

Their versatility makes FIBC Super Sacks popular in many different sectors:

- Agriculture: For animal feed, fertilisers, seeds, and grains.

- Construction: To move other aggregates, cement, sand, and gravel.

- Chemical Industry: For resins, granules, and powders.

- Food Processing: For dry food components as sugar, flour, and starch (needs food-grade bags).

- Mining: For other extracted materials, minerals, and ore.

- Pharmaceuticals: Bulk pharmaceutical ingredient special cleanroom-grade bags.

Advantages of Using FIBC Super Sacks

1. Operational Effectiveness

Super sacks let you handle products in bulk, therefore cutting the number of packages and simplifying transportation, unloading and loading procedures.

2. Less Packaging Waste

One FIBC can substitute 20 to 40 conventional tiny sacks, hence reducing packaging waste and improving work conditions.

3. Reduced Labour Costs

Dealing with less big bags translates into less time and labour required for packaging and distribution.

4. Custom Branding & Labelling

For brand exposure and compliance, bags can be printed with corporate logos, handling directions, and safety information.

5. Safety and Cleanliness

Manufactured in cleanroom settings with BRC, ISO, or FDA compliance, food-grade FIBCs are certified.

Advice on Safe Storage and Handling

- Although FIBCs are quite robust, appropriate handling is essential to prevent product loss or mishaps.

- Utilise the appropriate tools, such cranes with spreader bars or forklifts.

- To avoid rips, don’t drag bags on the ground.

- Exceed not the Safe Working Load (SWL) specified by the manufacturer.

- If bags are not UV-treated, keep them in a clean, dry location shielded from UV radiation.

- Carefully arrange bags; use pyramid or supported stacking to avoid collapse.

Environmental Issues

Many producers now provide recyclable and reusable FIBC Super Sacks as sustainability grows more crucial. If they satisfy safety and sanitary criteria, bags can be used several times. Polypropylene FIBCs can be recycled into plastic products at the end of their life cycle, hence lowering environmental effect.

Final Thoughts

By providing a consistent, affordable, flexible approach for managing enormous volumes of material, FIBC Super Sacks have transformed bulk packaging across sectors. For companies managing dry bulk commodities, their customisability, durability, and environmental friendliness make them absolutely necessary. Investing in high-quality FIBC Super Sacks will greatly improve your operational efficiency whether you are in agriculture, construction, chemicals, or food manufacturing, hence guaranteeing product safety.