When you think about packaging something in bulk—like grains, cement, or chemicals—you probably imagine a large, sturdy bag that can handle the load without tearing or giving in. That’s exactly what an FIBC bag, or jumbo bag, is made for. But have you ever wondered what makes some of these bags stronger or more durable than others?

It often comes down to something that’s not always obvious: GSM.

Let’s break it down in simple terms and understand why GSM isn’t just another technical term—but a key part of why your packaging works the way it should.

So, What Is GSM?

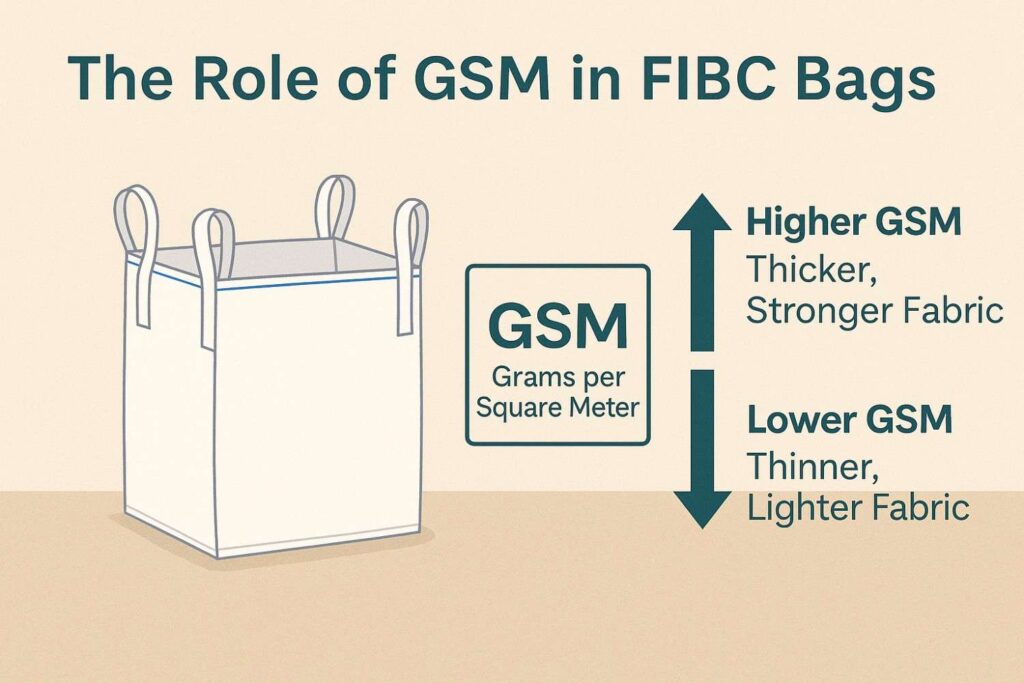

GSM stands for Grams per Square Meter. It’s a way to measure the thickness or density of the fabric used in making a jumbo bag.

Think of it like this: a thick winter blanket weighs more per square meter than a thin bedsheet, right? That’s the difference GSM makes. The higher the GSM, the thicker and stronger the fabric. And when you’re packaging 500 kg or even a ton of material, that difference really matters.

Why Should You Care About GSM?

1. It Decides How Much Your Bag Can Handle

The thicker the fabric, the more weight it can support. If you’re using the bag for something light like plastic pellets, a lower GSM might be fine. But for heavy stuff like cement or minerals, you’ll want a bag that can take the pressure—and that’s where a higher GSM makes all the difference.

2. It Keeps Your Bag from Tearing

Rough handling, stacking, lifting—bulk bags go through a lot. A stronger fabric (with higher GSM) resists tears, punctures, and general wear and tear. So, if your bag is going to be moved around a lot, this is something you really can’t overlook.

3. It Helps When Bags Sit in the Sun

If your bags are stored outdoors, sunlight can be a big problem. UV rays can weaken the fabric. But higher GSM fabrics can be treated with UV protection and handle sun exposure much better than thinner ones.

4. It Saves You Trouble (and Money) Later

Sure, thicker fabric may cost a bit more upfront. But a torn bag during transport? That could cost you way more. Think of GSM as a small investment in reliability and peace of mind.

Common GSM Ranges (And What They’re Good For)

| GSM Range | Best For |

|---|---|

| 120–140 GSM | Lightweight materials like powders or plastic pellets |

| 150–160 GSM | Everyday use – grains, seeds, or sand |

| 170–200 GSM | Heavy-duty loads – cement, stones, fertilizers |

| 200+ GSM | Extra strong or reusable jumbo bags, export packaging |

At Disha Jute, we help you pick the GSM that suits your exact need—nothing more, nothing less.

How We Get It Right at Disha Jute

At Disha Jute & Allied Products Pvt. Ltd., we take GSM seriously. Before any fabric goes into production, we test it in-house to make sure it’s exactly what your product needs. We don’t believe in one-size-fits-all. Whether you’re buying Q-Bags, U-Panel Bags, or Sling Bags, we’ll customize the thickness based on what you’re packing.

Because your product deserves packaging that doesn’t just work—it performs.

Not Sure What GSM You Need?

That’s completely okay. Most buyers aren’t 100% sure either—and that’s where we come in. Just tell us what you’re packing, how much it weighs, and where it’s going. We’ll guide you to the perfect bag thickness and build.

Final Thoughts: GSM Is a Small Detail That Makes a Big Impact

In the world of FIBC bags, GSM is more than a number—it’s the fabric’s promise to hold strong, stay safe, and protect your product from start to finish. The right GSM ensures you don’t face leaks, spills, or costly product loss. It’s the invisible strength behind every successful shipment.

So, the next time you’re sourcing jumbo bags, don’t just ask about size or color—ask about GSM. Your product (and your bottom line) will thank you for it.

Let’s Talk About Your Bulk Packaging Needs

Looking for expert advice on the right FIBC bag for your business? Reach out to Disha Jute today. We’ll help you choose the best bag with the right GSM—because when it comes to bulk packaging, every gram counts.