What is Jumbo Bag?

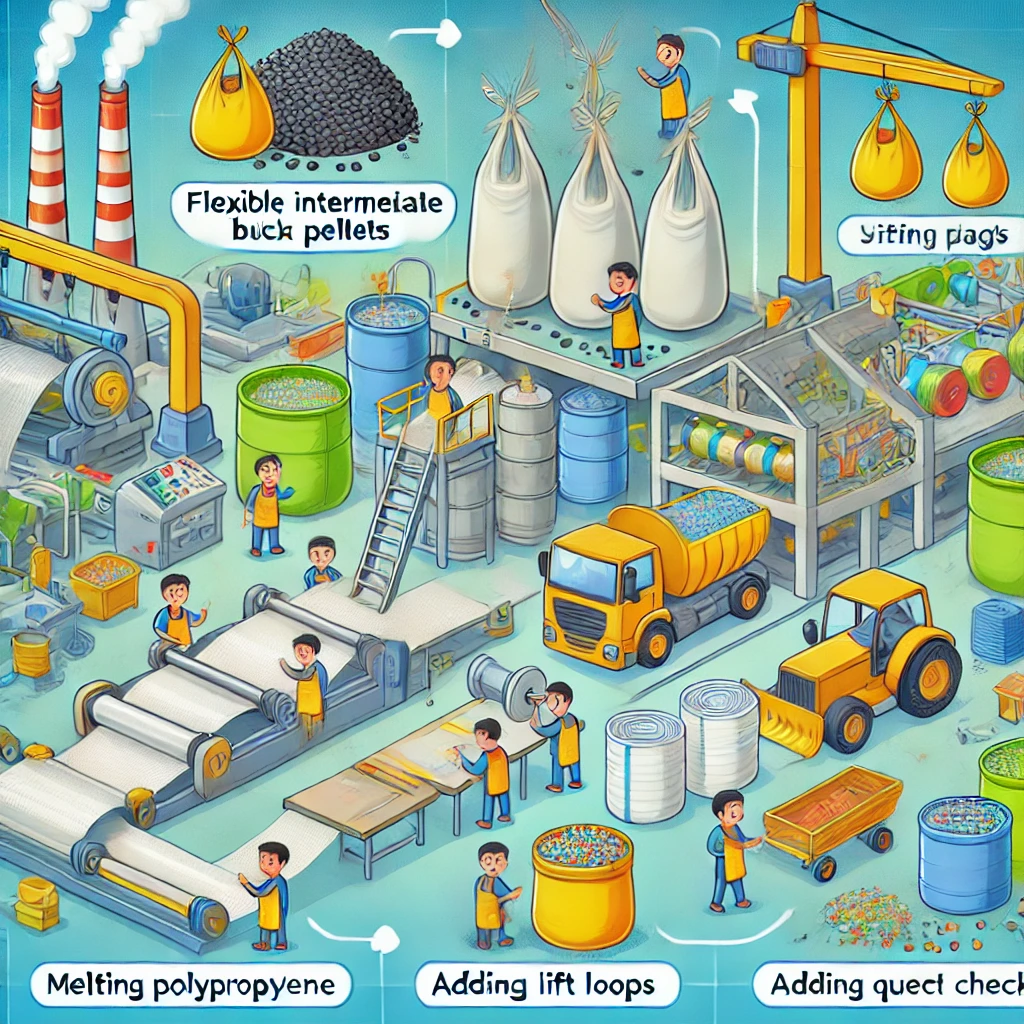

Large, sturdy, and flexible packaging options used to move and store dry bulk goods including cereals, chemicals, fertilizers, and building materials are jumbo bags—also known as Flexible Intermediate Bulk Containers (FIBCs). Typically made from woven polypropylene, a material known for its durability, flexibility, and lightweight properties. Let’s explore the step-by-step process of how jumbo bags are made?

1. Material Choice and Get-readyness

Jumbo bags are made primarily of woven polypropylene (PP). This stuff is selected for its cost-effectiveness, chemical resistance, and strength. The procedure starts here:

- Polypropylene Granules: Little plastic pellets make up the raw ingredient.

- Extrusion: Melted and extruded into long, thin tapes or filaments—the building blocks of the woven fabric—the pellets are

2. Creating the Fabric

The polypropylene tapes are spun into fabric using specialist looms once they have been ready:

- Strong, flexible fabric is created by the crisscross pattern of interweaving the tapes.

- The intended usage of the bag will determine whether strength, breathability, or waterproofing is desired, so the weave pattern can be changed to improve these factors.

The gigantic bag’s primary body is made from the resultant woven cloth.

3. Cut and sew.

The woven polypropylene fabric is then cut to fit the jumbo bag’s needed measurements.

- Usually featuring a body and several panels—such as the top, sides, and bottom—jumbo bags consist of panels and body.

- These parts are sewed together using industrial sewing machines with high-strength threads. Extra longevity is achieved using specialised stitches like overlocking.

4. Including Utility Attributes

Many times, jumbo bags have several elements meant to improve their usefulness and simplicity of usage.

- Strong loops, sewed into the sides or corners, make lifting with forklifts or cranes simple.

- Bags can feature spouts at the top for filling and at the bottom for content discharge.

- Certain bags may be laminated for increased durability or feature internal polyethylene liners for moisture control.

- Internal baffles are included to keep the bag stable and in form when loaded.

5. Test and Quality Control

For giant bags—especially those used for heavy or hazardous materials—quality is absolutely vital. Every bag is tested rigorously including:

- Making sure the bag can manage the Safety Factor (SF) need (typically 5:1 or 6:1) and the Safe Working Load (SWL).

- Examining that every seam and loop is strong and robust helps to ensure stitch integrity.

- If the bags are meant for fine powder or liquids, they must be leak-proof.

6. Custom branding and printing

Excellent printing techniques allow jumbo bags to be personalised with company logos, safety instructions, and handling rules.

7. Distribution and packaging

The bags are bundled flat or in bundles and delivered to end customers once they pass quality inspections. To keep integrity prior to distribution, they are kept dry and clean.

In conclusion

In the worldwide supply chain, jumbo bags are very important since they offer a cheap and effective way for handling bulk goods. Every stage in the manufacturing process guarantees that these bags satisfy the best criteria of strength, durability, and safety, from polypropylene granules to the finished stitched product.

For premium, bespoke jumbo bags, get in touch DITAN: Disha Jute and Allied Products Private Limited if you want further information about FIBCs or require bespoke solutions for your company.