Beginning

If you’ve ever been to a warehouse, building site, or farm, you’ve probably seen big cloth bulk bags stacked neatly or being handled easily by cranes or forklifts. FIBC bags, or Flexible Intermediate Bulk Containers, are what these bags are called. They make it safer and easier to move big things. But what makes these bags strong and easy to lift? Their lift loops hold the answer.

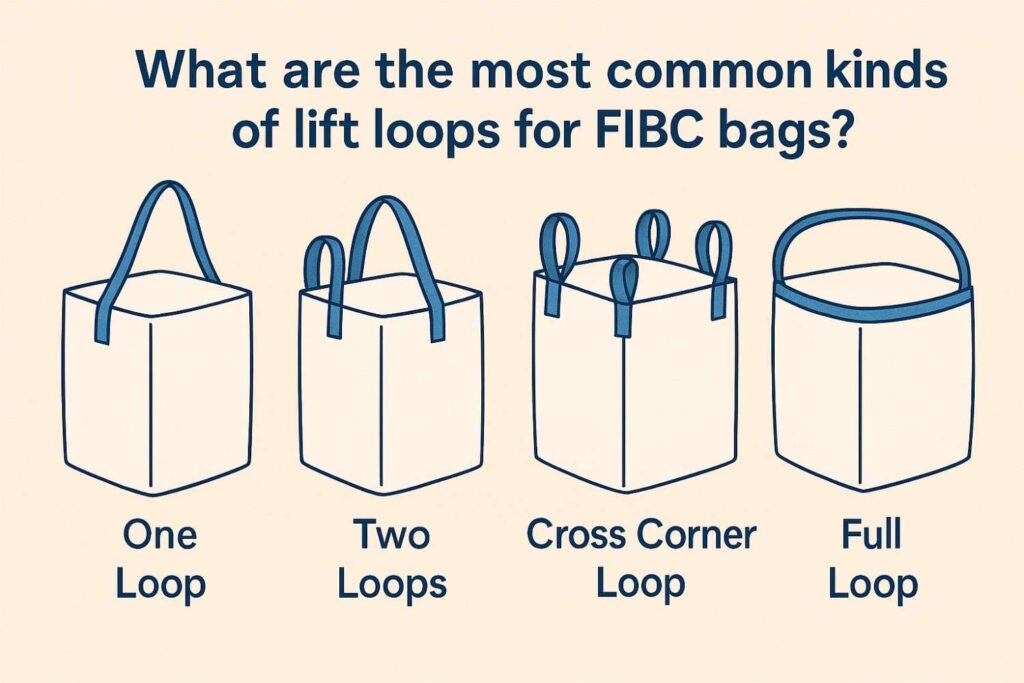

Lift loops are the unsung heroes of FIBC bags. It would be a logistical headache to move these huge containers without them. We’ll show you the most popular types of FIBC bag lift loops, how they function, and why it’s important to pick the proper one to keep things running smoothly and safely.

Why Lift Loops Are Important

Lift loops may seem simple, but they are very important for moving large amounts of stuff. These loops hold up the weight of the bag when it is being lifted, stop it from tearing, and make sure the load stays balanced. If a loop isn’t made well, it could cause mishaps, spills, or even damage to the bag and equipment.

Choosing the correct lift loop for your FIBC bag will not only keep you safe, but it will also make things go more smoothly. The right loop type helps keep workers and products safe and prevents accidents when you’re lifting fertiliser, grains or building materials.

Different kinds of FIBC lift loops

1. One Loop

With a single loop design, there is one loop on each corner of the bag. It’s simple and works well for lighter loads.

Pros:

- Easy to use and understand.

- More affordable than other designs.

- Good for materials that don’t need to be balanced in a complicated way.

Best for: Sand, light agricultural goods, or places where lifting isn’t needed very often or is quite simple.

2. Two Loops

There are two loops at each corner of the double loop, which makes it stronger and more stable. The load is spread out better, which lowers the stress on one location.

Benefits:

- Safely carries heavier things.

- Lessens the stress on the fabric.

- Stops slipping while lifting.

Best for: Chemicals, building materials, and other heavy industrial goods where safety is the most important thing.

3. The Cross Corner Loop

The cross corner loop design weaves loops over corners to give balance and extra strength.

Pros:

- Great for weights that are uneven or hard to handle.

- Keeps its shape when lifted.

- Lowers the chance of tipping.

Best for: bulk objects that aren’t always the same shape or processes that need to be moved around a lot.

4. The Full Loop

The whole loop goes all the way around the top edge of the bag, giving it the most lifting power.

Benefits:

- Best for loads that are quite hefty.

- Provides even support all the way around.

- Reduces tension and stops tears from happening.

Best for: Mining, heavy construction aggregates, or other big jobs that need a lot of load capacity.

How to Pick the Best Lift Loop

Choosing the correct lift loop isn’t just about the load; it’s also about the environment, how often you use it, and the sort of material. Think about these things:

- Weight Limit: Always pick loops that can handle the weight you need them to. Do not go above what the manufacturer says.

- Material Type: Loops need to be stronger for heavier, rough materials.

- How often they are used: Bags that are lifted several times a day need loops that can handle wear and tear.

- Safety Standards: Make sure the loops have passed safety tests from organisations like the UN.

Talking to manufacturers or suppliers will help you find a solution that fits the needs of your business.

Using it in real life

Many industries employ lift loops, and choosing the appropriate one can make or break your business.

- In farming: Double loops are often used on grain bags to keep them from spilling while they are being moved.

- Construction: Full loop designs can handle heavy materials like cement and sand, which keeps them stable.

- Chemicals: Cross corner loops safely move powders without the possibility of unexpected changes.

- Mining: Heavy-duty complete loops can hold a lot of weight, which cuts down on downtime and makes the job safer.

In every situation, picking the right loop design helps keep workers safe, avoid accidents, and make things run more smoothly.

Best Practices and Maintenance

Even the best lift loops need to be cared for. Here are some useful tips:

- Check regularly: Before each use, look for cuts, fraying, or other signs of wear.

- Don’t Overload: Going beyond the load limit can produce dangerous problems.

- Store Properly: To keep bags from getting damaged by UV rays and moisture, keep them in a dry, shady place.

- Gently clean: Get rid of dirt and grime without using strong chemicals that could damage the fabric.

A little care can go a long way towards keeping your baggage secure and lasting longer.

In conclusion

Lift loops are more than just straps; they are important equipment that help move large amounts of goods securely and quickly. Choosing the proper sort of loop makes sure that you can move both light grains and heavy building materials safely and without mishaps. It also makes you more productive.

Knowing the differences between single, double, cross corner, and full loops gives you the power to make smart choices that help your business and your team.

What to do

Do you need help picking the right FIBC bag lift loop for your business? Our team of professionals is here to help you choose the safest and most effective option. Get in touch with us immediately so we can work together to make bulk handling safer and easier!